Masters of Quality

Liz and Sven are our quality experts: they control it at every stage of our process, and they talk about it with you here!

What is your professional background?

Liz: I have a bachelor’s degree in food science and have worked in retail for a long time. This enabled me to understand the processes in the background as well as the many facets in the exchange with customers.

Sven: I studied food science, I did an apprenticeship as a food technologist in a coffee and bouillon manufacturing company. And I have 2 years of work experience in the dairy industry.

What is your current role at New Roots?

Liz: I am responsible for the operational tasks of quality assurance. Essentially, these are product and hygiene controls. I am approached when quality and food law issues arise.

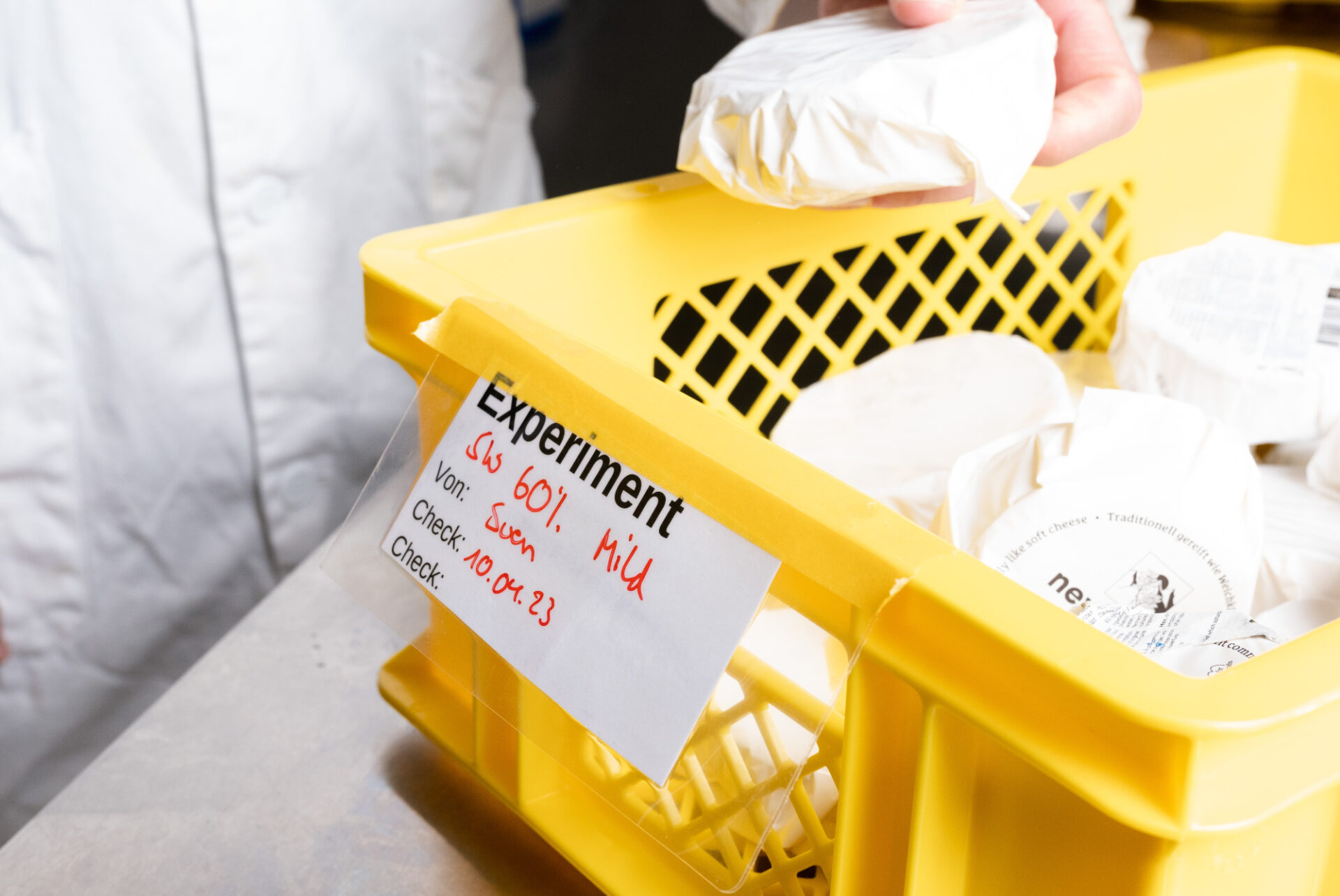

Sven: I work in many areas and have insights into different departments. My main job is scaling up the production of a new product. I have to understand what properties a product has and what the customer’s requirements are. Then I work closely with our engineers and production specialists to find the right machines, processes and packaging solutions. I perform a lot of tests, both on a large and small scale. The quality of products and their control is very important in the food industry. For this reason, during scale ups and tests, I frequently interact with the quality control department in order to determine the shelf life of products as quickly as possible and to guarantee the best possible quality of our products.

The first scale-up of a new product is always an exciting step into the unknown.

Can you describe how quality control works at New Roots?

Liz: All of our products are microbiologically and sensorially tested on a weekly basis. So I can judge whether they meet our quality standard or not. Close cooperation with the production team is very important in order to react immediately in the event of deviations. This requires a clear head and some assertiveness. With the constant implementation of quality controls, I am in daily contact with practically all departments. After all, we as a team are pursuing the same goal: to offer delicious and flawless products.

Sven: Once a new product has been developed in R&D, the challenge is to produce this product on our existing machines. To select the right processes and machines, I discuss with our specialists and deduce the best approach. After that I make first smaller tests to eliminate possible risks before a bigger test is made on the final plant. The first scale-up of a new product is always an exciting step into the unknown. After the first scale up, I make many shelf life tests with quality control and determine the shelf life date of the new product. I work closely with the quality control department there and support the creation of allergen concepts, the extension of HACCP concepts and the training of our production team.

What’s your favorite part of your job?

Liz: Since I naturally love diverse cuisine, the sensory evaluation of new products is always a highlight for me. It’s always a small success to discover the subtle differences with your senses – and not just with the list of ingredients.

Sven: I like the flexible working environment at New Roots, it never gets boring! My work is very interesting and varied. And I also like the relaxed atmosphere in the team at New Roots.

What does working for New Roots mean to you?

Liz: It means a lot to me to work in a company that aims to make a lasting impact on the food system. This inspiration is reflected in the mentality and daily commitment of the entire team.

Sven: After my studies and an eye-opening journey, I wanted to make a difference in the food industry. I wanted to be able to stand behind a product that was good for people and the environment. This is what I found at New Roots.

We as a team are pursuing the same goal: to offer delicious and flawless products.

You also like